ABOUT US

Embosal is one of the leading manufacturer of Steel Tubes and Pipes. Embosal Tube Mills are Located in Al Ghail (Ras Al Khaimah), United Arab Emirates with the installed combined capacity of 1.5 Million Tons per annum. We are equipped with advanced state of art production machineries in large well organized factories. We are designed to produce square and rectangular Steel tubes with size range of SHS 30x30x2mm to 800x800x40mm and RHS 35x30x2mm to 800x750x40mm.

Our Steel Pipe production line starting from 1 ” dia to 250” dia pipes in different thickness from 2mm to 80mm.All the products are widely used in machinery, large construction, bridge, airports, ship building purposes etc. we are one of the leading Manufacturer of Steel Tubes and Pipes in UAE. Our production Includes LSAW, SSAW and ERW.

MISSION

We will continue to be the first name in the region’s steel industry by reinforcing our assets, and resources in order to achieve growth, operational and organizational excellence by participating in the economical and positive social expansion of the United Arab Emirates.

VISION

We endeavor to be recognized as one of the leading and constantly growing force in the steel industry of the region, and to be admired for our business culture and adding value to our customers and enhancing inspiration to our people.

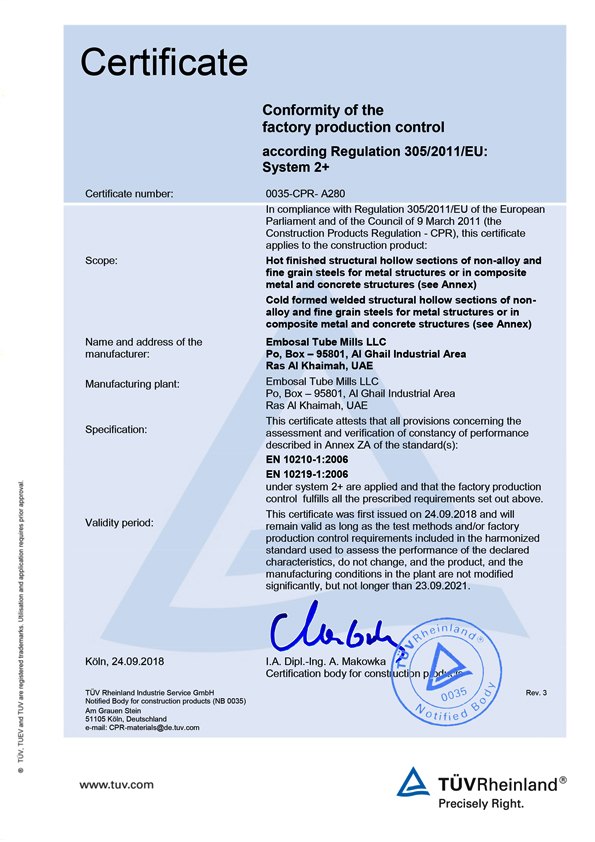

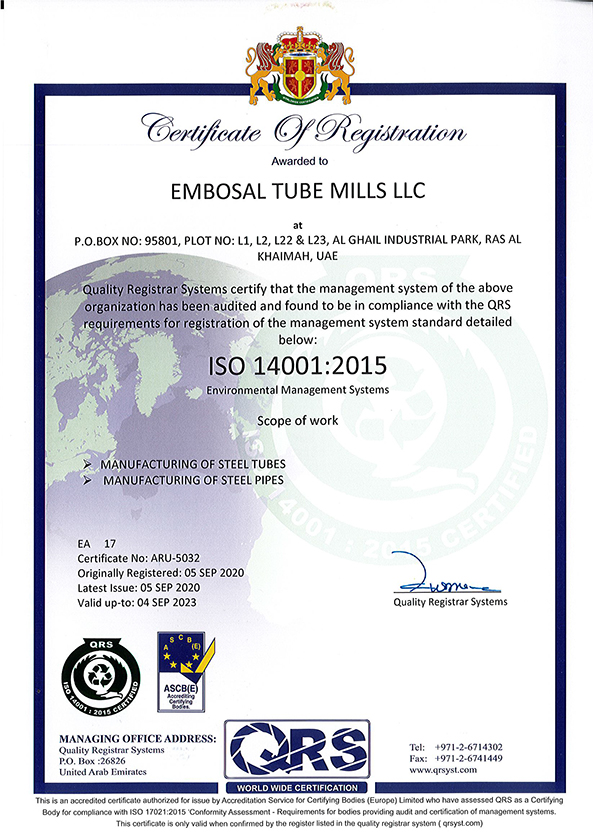

QUALITY ASSURANCE

Embosal Tube Mills is committed

enhancing its customers value with the product and services and to set industry standards for quality and performance. We strive to deliver the best and understand the value of continuous improvement by setting goals and objectives throughout the organization in order to ensure that we are meeting our customer expectations beyond their imagination.

QUALITY POLICY

We will continue to be the first name in the region’s steel industry by reinforcing our assets, and resources in order to achieve growth, operational and organizational excellence by participating in the economical and positive social expansion of the United Arab Emirates.

Coating Plant

Blasting & Painting

3PE Coating Plant

BLASTING & PAINTING 3PE COATING PLANT

BLASTING & PAINTING

In this method, dry abrasive is propelled against the surface to be cleaned so that rust, contaminates, and old paint are removed by the impact of the abrasive particles. Moreover, the surface must be cleaned of blasting residue before painting. This is usually done by blowing clean air across the surfaces.

3PE COATING PLANT

3PE coated steel pipe is commonly used in the pipeline project. As carbon steel pipe is widely used in pipeline systems for transportation of oil, gas, water and other fluids. In such cases, they should have high resistant to corrosive from chemicals, moisture, harmful environment and etc. So it is necessary to make pipes coating to anti-corrosion.

GALVANISING PLANT

Galvanization is the process of applying a protective zinc coating to steel or iron to prevent rusting

Galvanization is the process of applying a protective zinc coating to steel or iron, to prevent rusting. The most common method is hot dip galvanizing, in which the parts are submerged in a bath of molten hot zinc.

Hot dip galvanizing is the process of coating iron or steel with a layer of zinc by immersing the metal in a bath of molten zinc at a temperature of around 450 °C (842 °F). … Galvanizing is probably the most environmentally friendly process available to prevent corrosion

Enterprise Spirit

Innovative Spirit Dynamic Development

Operational Concept

Scientific Management High quality & efficiency Being Honest Considerate Service

Development Goal

Create Quality Enterprise Make Professional Products

Quality Guideline

To be the best