Embosal can manufacture non standard size & thickness of Tubes & Pipes on custom requirement.

Circular, Rectangular & Square Hollow Section

Welcome to Embosal Tube Mills L.L.C - Manufacturer of Steel Tubes and Pipes

Embosal Tube Mills the leading Steel Tube and pipe manufacturer, located in Al Ghail (Ras Al Khaimah), United Arab Emirates with the installed combined capacity of 270,000 Tons per annum. We are equipped with advanced state of art production machineries in large well organized factories to produce precision square and rectangular tubes with specification range of 30x30x3mm to 800x800x40mm and RHS 35x30x3mm to 800x750x40mm. Also we are equipped with other production line starting from 1/4 inch to 100 inch dia steel pipes in different thickness upto 70mm.We are the leading steel Pipe manufacturer in UAE, also we are the leading Steel tube manufacturer in UAE.

As a leading Steel Pipe Manufacturer in UAE we are specialized in producing large diameter higher thickness Standard and non standard SSAW, LSAW and ERW Pipes. We are also specialized in producing Jumbo Higher Thickness Standard and Non Standard Steel Tubes .

Size Range - LSAW PIPES

Pipe Diameter Range

9″-60″

Wall Thickness

6 – 50 mm

Pipe length

12M

Grade- S275JOH, S355J2H/JOH | Standard: EN10219 & EN10210

We can produce any custom Size /Thickness

Size Range - Tubes

Square Tube

30x30x3mm

–

800x800x40mm

Rectangular Tube

35x30x3mm

–

800x750x40mm

Technical Details

Chemical /Mechanical Composition

Grade- S275JOH, S355J2H/JOH | Standard: EN10219 & EN10210

We can produce any custom Size /Thickness

Special Shapes

Our Special Shape Products

Production Process

Production Process of Steel Tubes and Pipes

Get a Quote

Get a quote Form

Contact Us

Contact with us

WHY TO CHOOSE

EMBOSAL TUBE MILL

LOCAL MANUFACTURER

WIDE SIZE RANGE

NO MINIMUM ORDER QUANTITY

QUICK DELIVERY

SHARP EDGE TUBES

CUSTOM SIZE & SHAPES

VALUE ENGINEERING BENEFITS

APPROVED BY TUV RHEINLAND GERMANY

SUPERIOR MATERIAL

Embosal Pipe Mill production system begins with advanced metallurgy and clean steel making practices.

HIGH DIMENSIONAL ACCURACY

High uniform wall thickness and smooth finish free from nonmetallic incisions and surface defects provide pipe with a superior level of quality and excellent dimensional accuracy as well as high performance properties.

EXCELLENT QUALITY

Quality is strictly controlled through every production step to ensure pipe product .Testing and inspection includes full body UT, highly sensitive UT for weld seam and numerous mechanical tests.

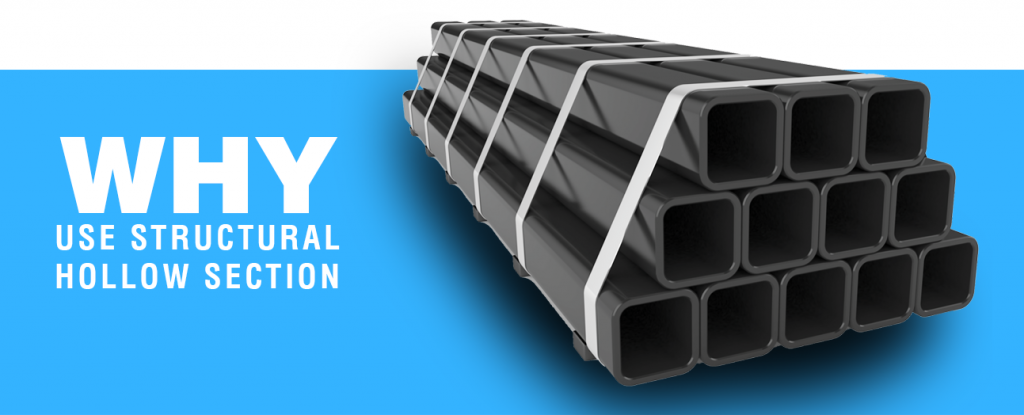

ADVANTAGE OF JUMBO HOT FINISHED SHS & RHS

Hot finished structural hollow sections are produced with a standard grade with yield stress of 355N/mn2, which fully complies with EN 10210 S355J2H on request also S + 460 can be used.

The sections have a Charpy impact minimum average energy of 27J at -20°C. All hot finished structural hollow sections have improved Corner profile of 2T maximum.

Hot finished SHS are manufactured in accordance with the European Standard for hot finished structural hollow sections EN 10210, with the technical delivery requirements of EN 10210-1:2006 and the dimensions and tolerances to EN 10210-2:2006 plus an improved corner profile of 2T Maximum.